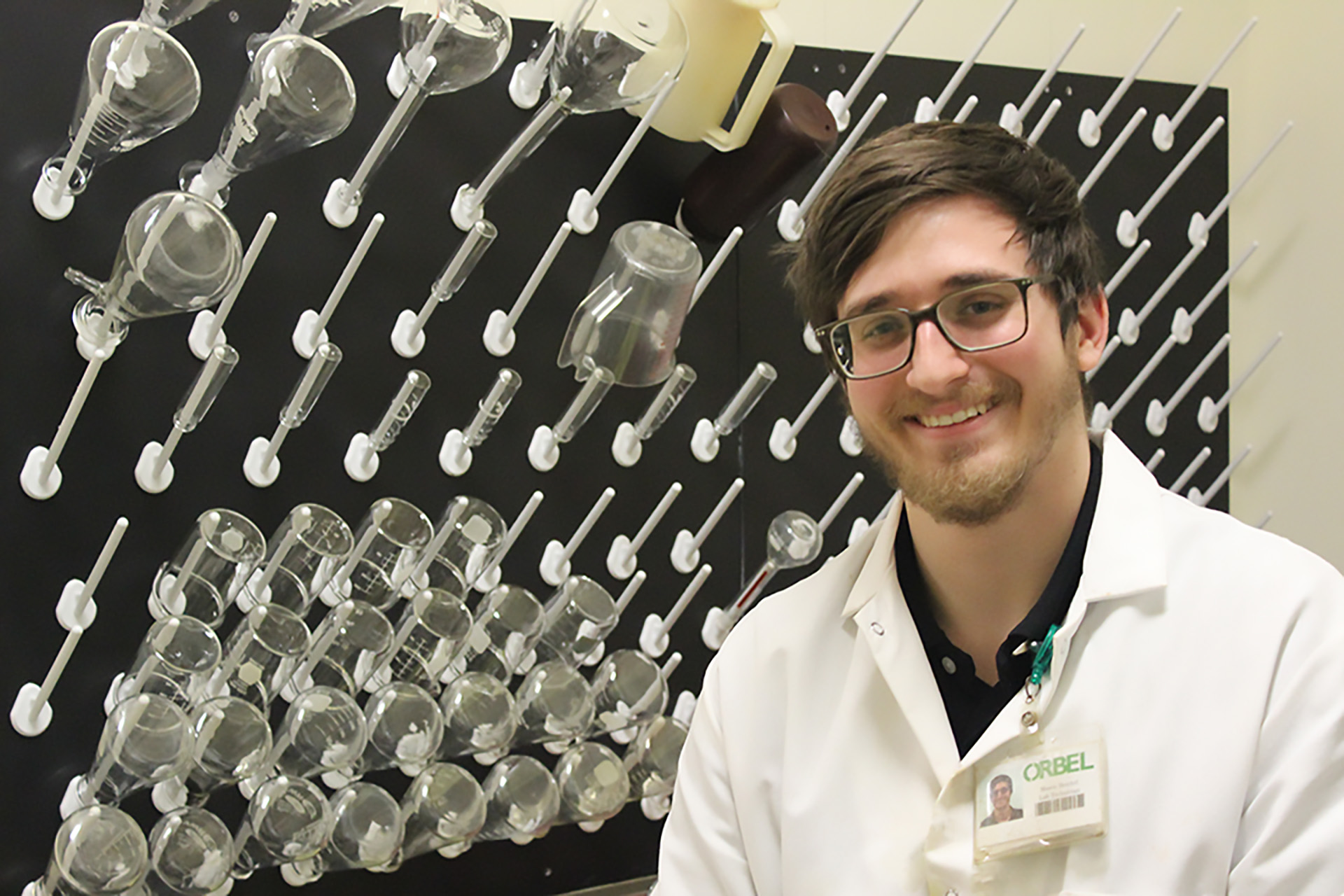

Since 1961, Orbel has worked closely with our customers to establish a comprehensive quality control program. Customer feedback, strict guideline adherence, and meticulous production documentation are critical to the ongoing success of every project. Internal product testing for all established quality parameters, along with a proven sample retention program, ensure that the highest quality standards are upheld.

Orbel has a full-service inspection department with capabilities including:

- Tensile Testing

- Hardness Testing

- X-Ray Fluorescence

- Adhesion Testing

- Solderability Testing

- 3D and Dimensional Coordinate Measuring

- Cross Section Analysis

- Tool Inspection and Calibration

- In-House Chemistry Lab

Orbel’s document generation capabilities include:

- First Article Inspections (FAI)

- Finite Element Analysis (FEA)

- Production Part Approval Process (PPAP)

- Advanced Product Quality Planning (APQP)

- End Item Data Packages (EIDP)

Orbel maintains the following documentation:

- Supplier certs

- Supplier lot and heat data

- All relevant quality control documentation for a product (more information)

Orbel conforms to the industry’s highest quality standards and has earned today’s most valuable quality certifications. To view all of Orbel’s quality certifications, and for a complete list of conflict-free smelter’s (CFSP) please click the link below.