AS9100 design-certified, Orbel is a light-gauge, tight-tolerance specialist backed by an engineering team with a long history of excellence. We keep design manufacturing and design engineering under one roof, from print development to full production.

Backed by Solidworks design software, Orbel designs with manufacturability in mind.

We develop routing schema that ensure best value—with the least scrap materials and the quickest processing times—and our application engineering team is part of the process from start to finish. We also have the capability to design manufacturing programs and systems to support any number of legacy products.

Orbel’s vertically integrated production facility allows us to design routings and manufacture components quickly and efficiently.

ASSEMBLY

Orbel’s dedicated assembly department combines in-house component assembly and fully vetted outside suppliers to ensure maximum value. We also harness the power of a dedicated stocking program that includes key components and materials.

Orbel’s expertise in the assembly of light-gauge, tight-tolerance materials includes welding, soldering, taping, polishing, riveting, and custom packaging. ESD (3D printed) packaging is also available. All assembly cycles are thoroughly documented.

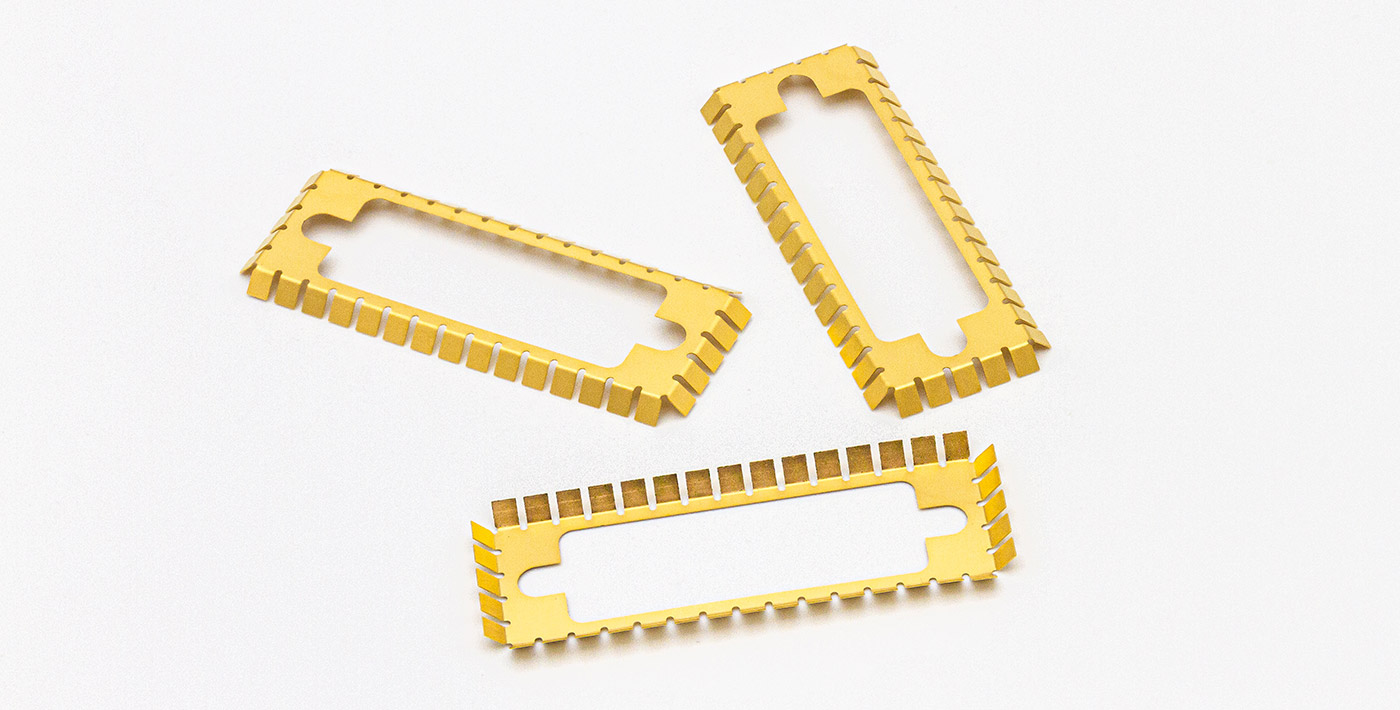

ETCHING

With both laser direct and photo tool imaging capabilities, Orbel produces etched precision metal solutions to the most intricate of component designs. We specialize in light-gauge, tight-tolerance components, from 0.0007″ in. (0.01778mm) to 0.020″ in. (0.508mm).

Standard and custom etched components are available in nickel silver, nickel, beryllium copper, stainless steel, cold rolled steel, brass, magnetic metals (mu-metal), nickel iron alloys (42 alloy and 52 alloy), and cobalt iron alloys.

FORMING

Any material Orbel can etch we can also form through the use of universal tooling, which reduces tooling costs when developing custom-formed metal components. In-house tool design, construction, and maintenance ensures repeatability and extremely tight tolerances.

Orbel is an expert in secondary forming, with in-house blank production that allows quicker turnaround times and greater tolerance control. State-of-the-art electric press brakes with integrated computerized programming enable exceptional repeatability and quality assurance.

HEAT TREATING

Orbel’s in-house, Nadcap certified beryllium copper heat treating, as well as fixture heat treating, allow us to adhere to extremely tight tolerances. For other materials, we rely on a trusted heat treating partner to deliver the same exceptional results and repeatability.

In-house hardness and tensile testing further ensures the quality of our heat-treated components. Tensile test methods employed by Orbel are in accordance with ASTM E8/E8M, Standard Test Methods for Tensile Testing of Metallic Materials.

PLATING

Orbel was founded as an electroplating facility in 1961, and we continue to evolve to meet changing industry needs. The plating materials we specialize in today include copper, nickel (sulfate, sulfamate, electroless), tin (bright and matte), solder (tin/lead), silver, gold, and passivation.

As design constraints push concepts to the limit, Orbel produces electroplated metal foils that hold the tightest tolerances, even at the thinnest of gauges. We also offer comprehensive reel-to-reel and rack plating services.

STAMPING

The industry’s leading custom stamping expert, Orbel utilizes state-of-the-art techniques to produce precision metal stampings. We use high-speed Bruderer presses as well as Minster and VO presses that can stamp with up to 90 tons of pressure.

In-house tool design, construction, and maintenance allows Orbel to handle every aspect of metal stamping, from design, prototyping, and short runs to medium- and high-volume production. We specialize in light-gauge, tight-tolerance precision.

QUALITY CONTROL

Orbel’s in-house quality control department ensures that we conform to the industry’s highest quality standards and that we maintain today’s most valuable quality certifications.

We utilize a range of quality control technologies including state-of-the-art optical comparators; tensile testing; plated deposit thickness testing (x-ray fluorescence); hardness, flatness, and solderability testing; and gauge calibration and inspection. We also conduct regular raw material and vendor supply reviews and inspections while maintaining strict document control.

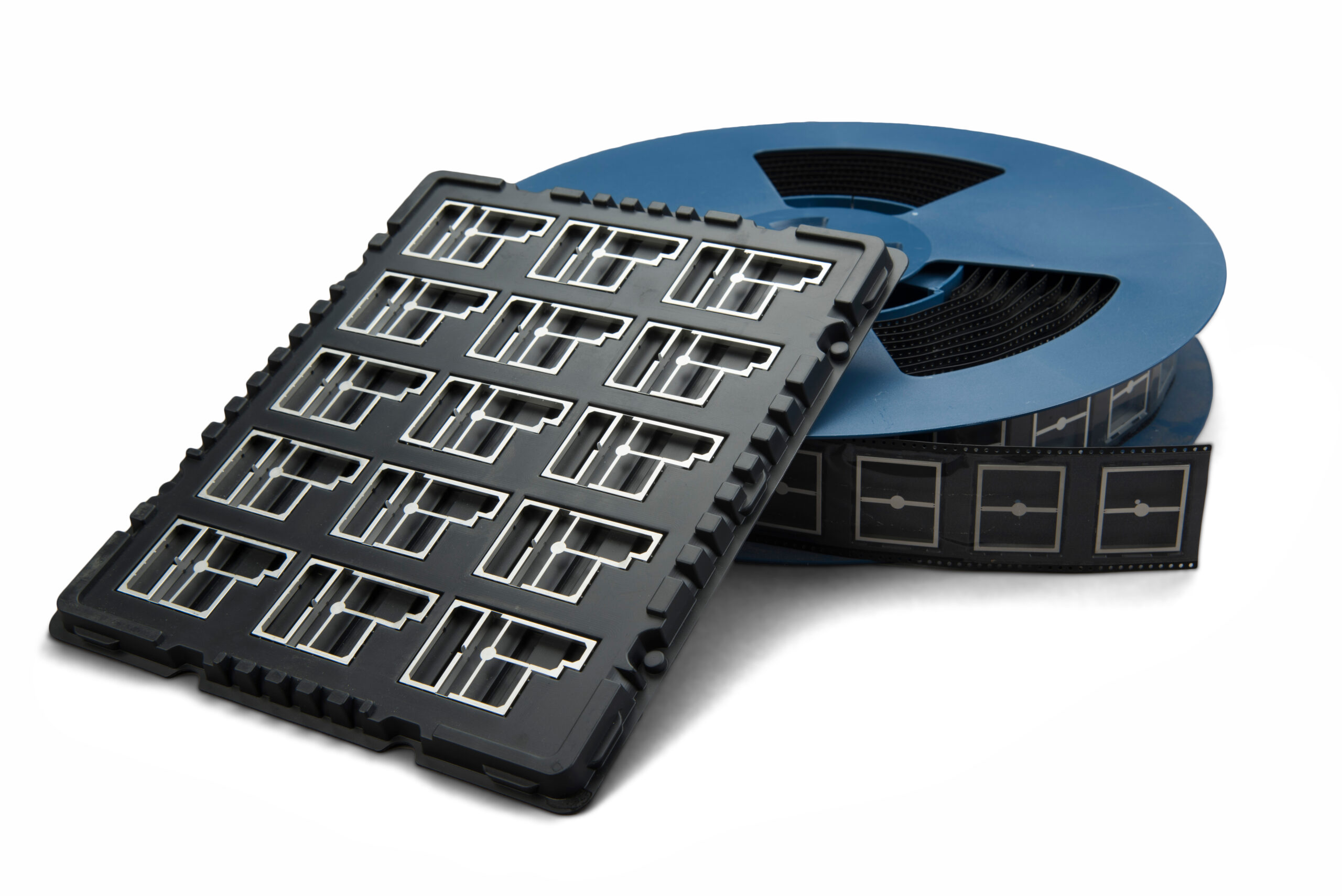

PACKAGING

Orbel’s in-house tape-and-reel packaging capabilities allow us to provide today’s preferred packaging for high-volume board level shielding, battery tabs, electrical contacts, and other components. Tape-and-reel is an economical automated SMT packaging solution that provides exceptional product protection during shipping and handling.

Orbel also offers tray packaging and other standard and custom packaging options to meet the needs of our customers. Barcoding is available in whatever format is required.